A Closer Look at the Cold Chain Journey

What happens to a perishable food item or a temperature-sensitive vaccine when it leaves the manufacturing facility? Since these items require constant refrigeration to maintain their freshness and efficacy, a standard supply chain simply won’t do.

Instead, they enter what’s known as a cold chain.

WHAT IS A COLD CHAIN?

A cold chain is very similar to a standard supply chain, with the important distinction being that the entire journey—from the point of origin to the final consumer—is low temperature-controlled. The cold chain typically includes refrigerated production, cold storage, and temperature-controlled transportation to extend the shelf life of perishable foods and other sensitive items.

A BRIEF JOURNEY THROUGH THE COLD CHAIN

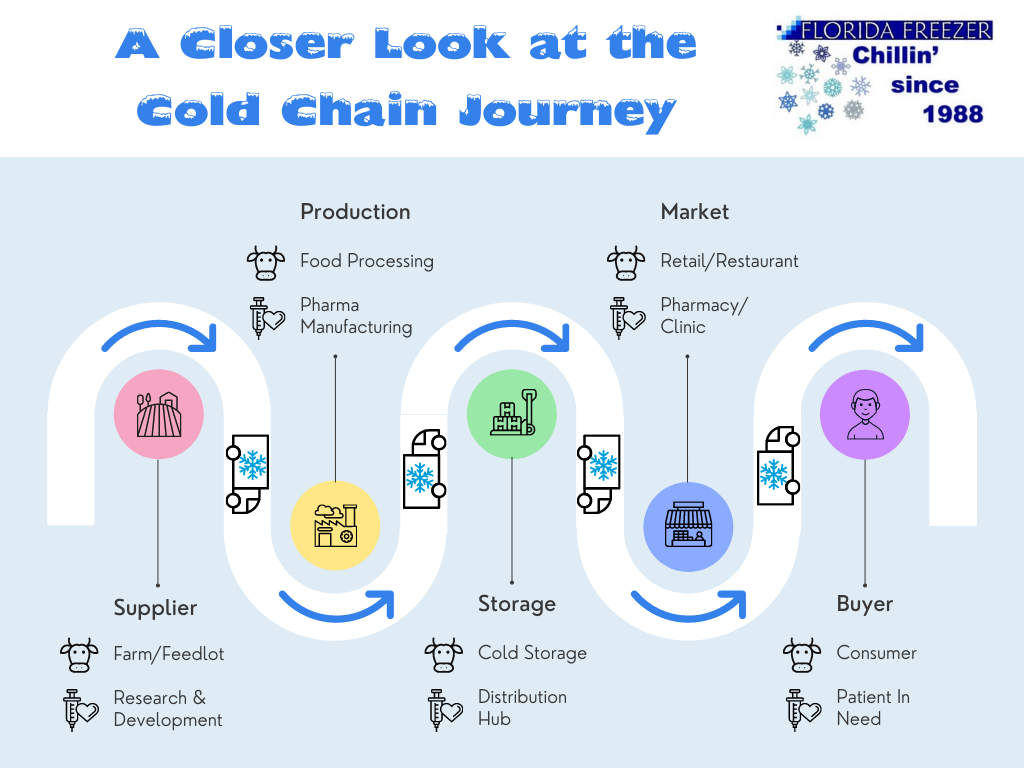

There are plenty of everyday items that require cold storage, and thus, a temperature-controlled journey through the five steps of the cold chain. To help visualize this journey, we’ve put together the following infographic featuring two of the most common cold chain products: meats and vaccines.

1. SUPPLIER

The first step in the cold chain is no different from a standard supply chain, as it begins with the suppliers themselves. These producers provide the raw materials and research necessary for further product manufacturing.

When it comes to meat, the producer is typically a ranch, saleyard, or feedlot. For other perishable foods like fruits and vegetables, it’s a farm, orchard, or another harvesting specialist.

In the case of vaccines, the chain begins in the research and development phase, where it needs to pass all medical trials before it can be shipped to the pharmaceutical manufacturers.

2. PRODUCTION

The raw materials are then shipped in temperature-controlled vehicles to the second step in the cold chain: Production. This is where the final product is created and packaged before being sent out into the world.

In the meat market, this step involves a food processor. This is where the carcasses are skinned, the meat and by-products separated, and the cuts are then chilled before final inspection.

Vaccines, on the other hand, are sent to a pharmaceutical manufacturing facility. There, the drug is synthesized at an industrial scale and then super-cooled, often with the use of dry ice.

3. STORAGE

When the meat product or vaccine is manufactured and packaged, it is once again transported by means of a specially refrigerated vehicle to the third stage in the cold chain: Cold storage and distribution.

In the food industry, perishable items are temporarily stored in regional cold storage facilities before they are sent off to local stores. A great facility will typically offer additional solutions as well, such as case picking, repackaging, and order fulfillment.

Vaccines and other medical treatments can either be stored in similar refrigerated facilities or in specialized national and regional distribution hubs. Considering the high-value nature of the drugs, extra security at these facilities is a common sight.

4. MARKET

Up until now, the temperature-sensitive cargo has traveled via mass shipments through global logistics firms. However, this “final mile” trip to the market requires a smaller, more local touch.

In the food and beverage industry, these markets range from small grocery stores and large supermarkets to restaurants, delis, and other foodservice providers.

When it comes to vaccines and other medical shipments, they primarily get sent to pharmacies, hospitals, clinics, and other healthcare facilities around the world.

5. BUYER

Just because your products are ready for the consumer doesn’t mean the cold chain journey is complete. Each item will still need to be stored or displayed in a refrigerated case until they are purchased and either consumed or administered.

Thanks to the ingenuity and logistical prowess of the cold chain, by the time the product reaches the end buyer, it is still at its peak freshness or efficacy.

While your customers and patients may not realize all the hard work that went into getting them their frozen sirloin steaks or Covid-19 booster shots, at least now you do.

.jpg)

CONTACT THE COLD CHAIN LOGISTICAL EXPERTS AT FLORIDA FREEZER

Your customers rely on you to consistently deliver high-quality products, and you can rely on Florida Freezer to help get them there.

Here are 6 Reasons to trust Florida Freezer with your cold chain storage and shipping needs:

- We have dozens of logistical services and offer customizable packaged solutions.

- Our business continues to grow, with recent expansions to our cold storage operations.

- We’ve been in the transportation and warehousing industries for over 50 years, and have served customers across dozens of different industries.

- We are proud members of the World Food Logistics Organization, the International Association of Refrigerated Warehouses, The World Group Cold Logistics Network, and more.

- Our team of dedicated supply chain professionals is always ready with a smile and a helping hand to work with our clients on a personalized basis.

- We have decades of proven success stories and satisfied customers. Give us a call today and we’ll tell you all about them.